|

Servo presses - Press technology | Ortlinghaus

Servo presses are used in the automotive industry as well. These press types generate forming energy directly by large high-torque electrical motors, without the need to install a flywheel and clutch-brake unit. For safety reasons and to fulfill legal requirements, it is necessary to install a reliable safety brake.

Ortlinghaus is the leading manufacturer of these brakes used in the automotive industry and supplies several press manufacturers with both standard and specially designed safety brakes, too.

Drive concept 1 - Servo presses

Hydraulic brake | Series 022

Hydraulically released multi-plate brakes and plates with sintered or organic lining

The 022 series is one of the most successful Ortlinghaus products. Well over one million units are in service around the world wherever safety brakes with an extremely long service life and quality without compromise are required. In mining equipment engineering, these multi-plate brakes are used in travel/drive brake and slew drive brake applications.

The advantage of these wet-running, hydraulically released and spring-applied multi-plate brakes is the high torques they achieve in compact dimensions. Hydraulically actuated brakes are also available as a special version. The spring-loaded brakes are safety brakes, which automatically work in cases of pressure failure. The brakes can achieve full torque even when there is no pressure.

- Torque: 1,000 - 30,000 Nm

|

|

|

|

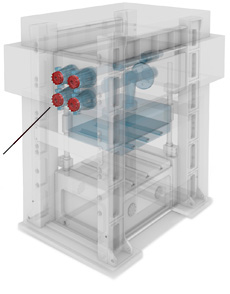

Prot.act – Hydraulic brake | Series 170

Presses driven directly by high-torque electrical motors

With the 170 model series, Ortlinghaus has developed a hydraulically released and spring-loaded brake with dry-running friction elements specifically developed for servomotor-driven presses. The brake is normally used as a holding brake for stationary machines, but can also be used as a safety brake for emergency stops.

The brake is characterized by its minimal space requirements, low moment of inertia of the parts rotating with the drive motor, and short switching times. Designed as a multi-disc brake, it can transfer high torque. Thanks to its enclosed design, the brake also operates with low external pollution and minimal noise. It conforms to the European safety standard DIN EN 692 and is largely maintenance-free.

Due to the design format with friction pads, the axial mobility of the friction elements when operating the brake is possible without moving metallic contact points. Thanks to the dry-running principle, no undesired residual torque develops during normal operation of the press with the brake open.

- Torque: 1,875 - 60,000 Nm

- Rotations per minute: 350 - 3,000 min-1

- Outside diameter: 284 - 762 mm

- Bore diameter:65 - 160 mm

- Length:94 - 284 mm

|

|

|

|

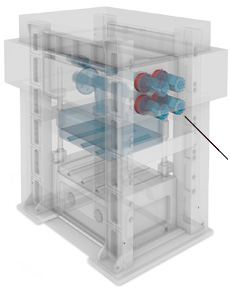

Drive concept 2 - Servo presses

Prot.act – Hydraulic brake | Series 171

Hydraulically released dry-running brake with friction pads

With the Prot.act model series, Ortlinghaus has developed a hydraulically released and spring-loaded brake with dry-running friction elements specifically developed for servomotor-driven presses. The brake is normally used as a holding brake for stationary machines, but can also be used as a safety brake for emergency stops.

The brake is characterized by its minimal space requirements, low moment of inertia of the parts rotating with the drive motor, and short switching times. Thanks to its enclosed design, the brake also produces little external pollution and minimal noise. It conforms to the European safety standard DIN EN 692 and is largely maintenance-free.

Due to the design format with friction blocks, the axial mobility of the friction elements when operating the brake is possible without moving metallic contact points. Thanks to the dry-running principle, no undesired residual torque develops during normal operation of the press with the brake open.

With the Prot.act servo brakes, we have designed two size variants (Prot.act 90 & Prot.act 94) for integration in front of the Siemens high-torque motors 1FW3 and 1FW4. The Prot.act flanges are exactly the same dimensions as the Siemens motor flanges, which allows a slim but compact and robust drivetrain combination.

- Torque: 10,000 - 63,400 Nm

- Rotations per minute: 0 - 1,500 min-1

- Outside diameter: 680 - 1,125 mm

- Bore diameter: 130 - 220 mm

- Length: 161 - 172 mm

|

|

|

|

|

|